CIP X PROCESS

CIP cleaning has the function of guaranteeing the chemical and microbiological quality of a process system making it qualitatively and quantitatively repeatable and reproducible.

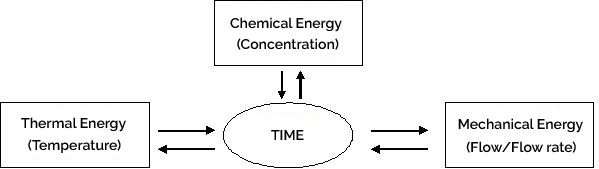

Its cleaning capacity, ie its efficiency, is characterized by 4 parameters, they are:

As an elementary postulate, one has the parameters that are interrelated inversely, that is, in order to maintain the efficiency of cleaning any pulse or instability that occurs in one of the parameters must entail in an opposite pulse in the others in order to balance the system.

CIP cleaning is characterized by its cleaning program. A cleaning program consists of a flow rate, a temperature, a time and a detergent concentration, which are generally determined by the production process in order to ensure a minimum cleaning efficiency that depends on the product, and the quality desired for the product. design of the plant equipment.

CIP process control

Generally the CIP can be defined through a control loop with the four parameters of the process interacting constantly. The flow, concentration and temperature correspond to the input variables of the control loop and the time to the output variable. We have:

• Flow: it is measured in the discharge of the pressure pump, or feed, of the CIP since this will be the same in every line or object of the process to be cleaned, so it is necessary to use a flowmeter, (Reynolds number = 100,000) and thus the fluid velocity (Reynolds x kinematic viscosity / diameter) and consequently the flow rate to be used in the given pipe (velocity / area) .

• Temperature and Concentration: are measured at the CIP plant at the end of the return lines of cleaning solutions taking as a principle that if the values taken are equal to or higher than those fixed, they will certainly be at the points of the process being cleaned, so it is necessary to use a temperature transmitter and conductivism. For the correct dosage of chemical concentrates, we are predicting the use of flow meters so that the over dosage does not occur and thus is guaranteed the consumption of point concentrates.

• Time: the time is counted by the CIP control system and changed according to the system input variables. The control logic is based on a timing switch according to the input variables. If one or more of the input variables are lower than the preset values, the time count is stopped until all of them return to values equal to or higher than their set points when the count is restarted.

! Note

• The cleaning efficiency of the system is directly related to the active principle of the chemical formulations. Provided that the required specifications are met for product removal on the equipment to be sanitized, the equipment reproduces the parameters requested by the supplier of the chemical scheduler, among them time, temperature, flow and conductivity.